At Miracle Welding, we offer passivation and electrochemical weld cleaning services for stainless steel, aluminum, and other metals, while adhering to rigorous industry standards. We use state-of-art equipment ensuring efficient, high-quality results that will extend the life of your metal products.

Passivation for Stainless Steel and Aluminum

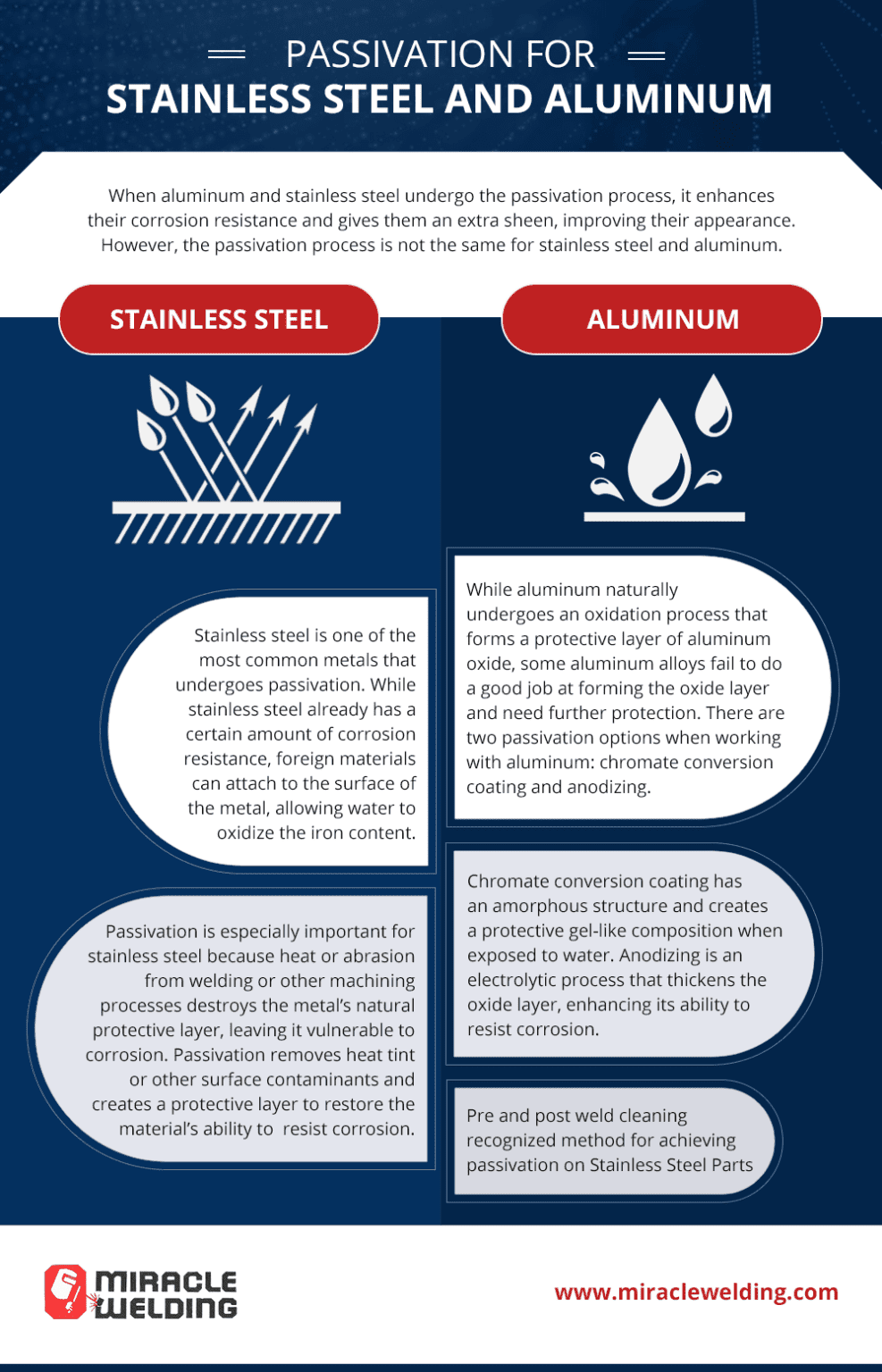

When aluminum and stainless steel undergo the passivation process, it enhances their corrosion resistance and gives them an extra sheen, improving their appearance. However, the passivation process is not the same for stainless steel and aluminum.

Stainless Steel

Stainless steel is one of the most common metals that undergoes passivation. While stainless steel already has a certain amount of corrosion resistance, foreign materials can attach to the surface of the metal, allowing water to oxidize the iron content.

Passivation is especially important for stainless steel because heat or abrasion from welding or other machining processes destroys the metal’s natural protective layer, leaving it vulnerable to corrosion. Passivation removes heat tint or other surface contaminants and creates a protective layer to restore the material’s ability to resist corrosion.

Aluminum

While aluminum naturally undergoes an oxidation process that forms a protective layer of aluminum oxide, some aluminum alloys fail to do a good job at forming the oxide layer and need further protection. There are two passivation options when working with aluminum: chromate conversion coating and anodizing.

Chromate conversion coating has an amorphous structure and creates a protective gel-like composition when exposed to water. Anodizing is an electrolytic process that thickens the oxide layer, enhancing its ability to resist corrosion.

Pre and post weld cleaning recognized method for achieving passivation on Stainless Steel Parts

Electrochemical Weld Cleaning for Passivation

Electrochemical weld cleaning is a passivation process suited for metals that have undergone welding. During the welding process, corrosion-resistant properties are depleted by contamination or by the formation of chromium carbides on the metal’s surface.

There are two methods for electrochemical weld cleaning. The workpiece can either be submerged into an electrochemical bath that is typically filled with an electrolytic solution, or it can be swabbed with solution-soaked carbon fiber brushes or pads. When the bath, pad, or bush is exposed to an electric current, any contaminants or impurities on the metal’s surface will oxidize and dissolve, creating a surface that is corrosion-resistant and aesthetically pleasing.

Other Passivation Techniques

Surface oxides and other conditions of the metal’s surface affect its corrosion resistance. In addition to electrochemical weld cleaning, there are many other passivation techniques to improve the material’s surface. These techniques include:

- Anodizing. Anodizing involves the process of submerging a metal, such as aluminum, titanium, and magnesium, in an electrolytic solution which is then exposed to a positive electrical charge. This charge attracts negatively-charged ions, which then bond to the surface of the metal, creating a protective oxide layer.

- Galvanizing. Galvanizing is the process of coating steel or iron parts with zinc, creating a corrosion-resistant layer. This method is common for small hardware and outdoor fencing for its low cost but offers little physical protection or durability.

- Bluing. Similar to anodizing, steel is submerged into an electrolytic solution that gives the metal a blue finish. The surface will resist corrosion and rust but requires frequent oiling to maintain resistance.

- Chrome plating. Chrome plating is a plating process known for creating a polished, shiny surface that is hard and durable. This method is used for both metals and plastics, but the material requires complete re-plating if the chrome starts to flake or peel.

Passivation Services from Miracle Welding

Passivation techniques are critical to enhancing corrosion-resistant properties of stainless steel, aluminum, and other metals. At Miracle Welding, we are a family-owned business that has offered high-quality metal products and welding services for over 43 years. Our highly-skilled staff will work with you to meet your passivation needs while providing excellent customer service. To learn more, contact our experts or request a quote today.