Heavy Metal Fabrication

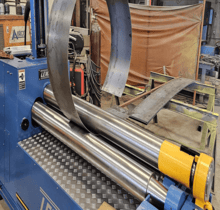

The heavy metal fabrication services by Miracle Welding Inc. provide large and heavy component fabrications for commercial and industrial applications. We offer fabrication methods such as pipe bending, forming, cutting, sawing, machining, pressing, punching, and welding. Working with aluminum, carbon steel, copper-nickel, iron, sheet metal, stainless steel, steel, and steel plate enables us to fabricate components for most industries. Our facility can accommodate parts that weigh up to 20,000 lbs. We can bend material to angles from 0° to 180°; our bending diameter is .5″ to 2″ with a wall thickness of .058″ to .120″ for schedule 5 to 40. Cutting capabilities can accommodate lengths of up to 60′ and a cutting width of up to 18″ x 21″. Our equipment will turn parts with a diameter of up to 17″. Parts up to 96″ long, up to 50″ wide, and up to 24″ high can be machined, and we offer a rolling thickness of up to 3″, and a tapping diameter of up to 3.50″. We work to tightest tolerances of ±1/16″. In addition to heavy metal fabrications, we offer assembly, finishing, and painting services.

We are experienced fabricators that serve the commercial, industrial, building, construction, and machine building industries. To learn more about our heavy metal fabrication service, please see the table below or contact us today.

Projects

- Fabrication of Steel Crane Beam for the Pre-Cast Industry

- Fabrication of a Steel Interstate Barrier for the Transportation Industry

- Machining and Welding of a Stainless Steel Jet Washer for the Aerospace Industry

- Fabrication of Stainless Steel Hardware for the Construction Industry

- Custom Fabrication of Steel Stairs & Railings for the Commercial Industry

Heavy Metal Fabrication Service Capabilities

- General Capabilities

-

Large Components

Heavy Components

- Fabrication Method

-

Pipe Bending

Forming

Cutting

Sawing

Machining

Pressing

Punching

Rolling

BevelingTapping

Threading

Flame Cutting

Plasma

Grinding

Power Brushing

Painting

Welding

Rotary Draw Bending

- Materials

-

Aluminum

Carbon Steel

Copper-Nickel

Iron

Sheet MetalStainless Steel

Steel

Steel Plate

Structural Steel

- Raw Material Forms

-

Sheet

Plate

Strips

Rounds

Squares

Flats

Angles

PipeTubing (Round, Square, Rectangular)

Channel

Threaded Rod

Rebar

Bar Grating

Expanded Metal

Bar Stock

- Bending Angle

-

0 to 180°

- Bending Diameter

-

.5 to 2 in

- Bending Wall Thickness

-

Schedule 5 to 40

.058 to .120 in

- Cutting Length

-

Up to 60 ft

- Cutting Width

-

Up to 18 in

- Cutting Height

-

Up to 21 in

- Turning Diameter

-

Up to 17 in

- Machining Length

-

Up to 96 in X

- Machining Width

-

Up to 50 in Y

- Machining Height

-

Up to 24 in Z

- Rolling Thickness

-

Up to 3 in

- Tapping Diameter

-

Up to 3.50 in

- Weight

-

Up to 20,000 lb

- Tolerance (+/-)

-

1/16 in

- Fabricated Products

-

Machine Frames

Heavy Plate

- Additional Services Provided

-

Assembly

Finishing

Painting

- Production Volume

-

Medium to Large Repeating Business

Additional Information

- Industry Focus

-

Commercial

Industrial

BuildingConstruction

Machine Builders

O.E.M.

- Intended Application

-

Heavy Machinery

Mezzanine

Handrails

GatesWeldments

Beams

Tanks

- Industry Standards

-

AISC (American Institute of Steel Construction)

ANSI (American National Standards Institute)

ASME (American Society of Mechanical Engineers)

ASTM (American Society for Testing and Materials)

AWS (American Welding Society)

DOT (Department of Transportation)

Mil-Spec (Military Specifications)

- File Formats

-

Bend-Tech SE

Structural Material Manager

Drafix (SolidEdge)BIMsight

Robo-Met 3D (UES)