Custom Hardware Fabrication for Construction Industry

A manufacturer of pre-cast concrete walls needed a high volume custom metal fabricator to supply various hardware components used in their wall assemblies. The components would be fabricated from stainless steel, as well as other various metals. The volume they required was approximately 15,000 individual pieces per month, and is usually only measured in tons. Items varied in size up to 8″ x 8″, and up to 1″ in thickness. Fabrication utilizes our plasma cutting and sawing capabilities, as well as drilling and burning. Parts that were not composed of stainless steel, required painting and galvanizing, which was done in-house.

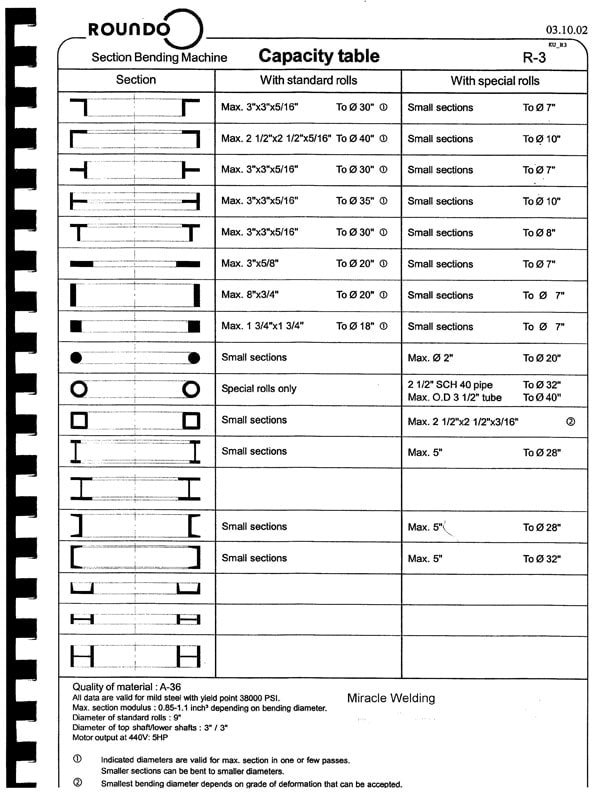

The volume and quantity produced on a regular basis is a testament to Miracle commitment to meeting our customer’s needs.

For more on what Miracle can do for you, contact Miracle Welding directly.

Highlights of this custom metal fabrication project

- Capabilities Applied/Processes

-

Drilling

BurningPlasma Cutting

Sawing

- Tightest Tolerance

-

1/16 in

- Material Type

-

Steel

Stainless SteelMiscellaneous Metals

- Material Thickness

-

Up to 1 in

- Product Length

-

Up to 8 in

- Product Width

-

Up to 8 in

- Material Finish

-

5 ft

Priming

GalvanizingStainless

- Resistances

-

Corrosion

- Industry for Use

-

Construction

Commercial

- Volume

-

15,000 per month (usually measured in tons)

- Standards Met

-

AWS D1.1

Building CodesAISC

- Product Name

-

Angles

Frames

FormsPanels

Tubes

Flat Bars

- Design Work

-

CAD Modeling

- Drawing Type Accepted

-

SolidWorks

- Product Description

-

Hardware for precast concrete walls to be hung on.