Press Brake Forming

At Miracle Welding Inc., we specialize in providing premium welding solutions. However, we also offer a variety of other custom metal fabrication services—including press brake forming—to serve the needs of our customers.

Press brake forming is a fabrication process used to bend sheet metal along a straight axis. It accommodates a variety of ductile materials and end shapes. The parts and products produced through the process find use in a wide range of industrial applications. Below we provide an overview of the process, including what it is, what industries it is used in, and what capabilities we offer at Miracle Welding.

An Overview of the Press Brake Forming Process

Press brake forming is a mechanical forming process that uses specialized matched punch and die sets (generally with “V” or “U” designs) incorporated into press brake equipment. The latter is available in mechanical, pneumatic, hydraulic, and servo-electric variations. During operations, the machine drives the punch component into the workpiece, forcing it to conform to the shape formed by the punch and the die. Since the materials used in such operations are highly ductile—such as aluminum, brass, steel, and stainless steel—the workpiece readily takes on and maintains the desired shape. Each bend in the part or product design requires a separate cycle to form.

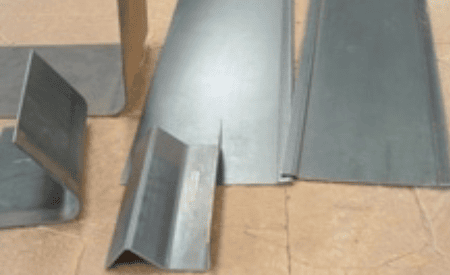

The press brake forming process can produce a variety of shapes, each of which is attained by using an appropriate punch and die set. Some of the most common include:

- 0 to 90° air bending – 18ga. to 3/8”

- Acute up to 14ga.

- Channel and gooseneck

- Flattening and hemming

- Hat channel and open hat channel

- Offset and M.T. offset (for oven panels)

- Radius punches to 3” diameter

- Urethane film when needed

- Wipe die

Industrial Applications of Press Brake Forming

In the industrial sector, press brakes are used to form parts and products for a wide range of industries, including the following:

- Aerospace

- Agriculture

- Automobile

- Energy

- Machining

- Marine

- Metallurgy

- Petroleum

- Power generation

- Transportation

At Miracle Welding, we’ve successfully completed numerous press brake forming projects. One example involves a customer in the overhead crane industry. Our company’s reputation for quality and competitive prices drew their attention, and they approached our team with a request for a walkway constructed from 3/16-inch tread plates. Armed with state-of-the-art equipment and years of metal fabrication experience, we were well-equipped to take on the job. While the customer supplied the cut tread plate pieces, we needed to form and assemble each piece to fit the design. Our 200-ton, 12-foot press brake allowed us to produce the assembly—measuring 44 inches by 120 inches—with parts made to ±.0625 inch tolerances. Additionally, the precision and accuracy we achieved allowed the walkway to be assembled end-to-end without welding. The customer was highly satisfied with the project results and currently maintains a monthly order of 200 walkways.

Contact Miracle Welding for Your Press Brake Forming Needs

The press brake forming process plays a critical role in many industries. It is used to produce simple components (e.g., brackets) to complex assemblies (e.g., metal housings or structures). For customers who need high-quality press brake forming services, Miracle Welding is the ideal partner.

At Miracle Welding, we use press brake forming to produce chutes, panels, stair parts, tread plates, and more from sheet metal. To learn more about our fabrication capabilities and how we can meet your custom specifications, contact us or request a quote today.